induction furnace crucible manufacturer

Induction Furnaces and Their Crucibles – What is an Induction Furnace?

An induction furnace is a type of furnace which uses electromagnetic induction to heat objects. It is used for melting and heating metals such as steel, aluminum, copper, and nickel. The furnace creates a magnetic field which induces currents in the metal to heat it up.

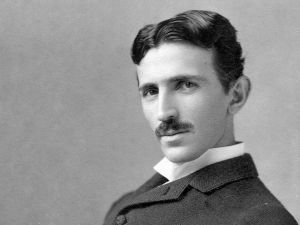

The induction furnace was invented in 1891 by Nikola Tesla and George Westinghouse. Induction furnaces are mainly used for industrial purposes such as heating metal bars or melting metal into liquid form. They are also used for annealing glass or ceramics to produce a desired shape and texture for the material.

Five Crucible Types for different Industries

Crucibles are a type of furnace that is used in industries such as the steel industry, glass industry, and pottery. They are used to melt materials that are too hard or brittle to be melted by other furnaces.

Crucibles are also used in the following industries:

– Steel industry: It is mainly used in the steel industry for melting pig iron into liquid iron.

– Glass Industry: Crucibles are mainly used in the glass industry for melting raw material like sand, limestone and dolomite into molten glass at high temperatures.

– Pottery Industry: Crucibles are mainly used in pottery industries for melting clay pots and ceramics into liquid clay at high temperatures.

How to Choose the Right Crucible for Your Need

The crucible is the container where you melt the metal. The type of crucible you need depends on what you are melting and what your needs are. For example, if you need to melt a lot of metal at once or if you have a large project, then you would want to use a selective melting crucible. If you need to melt just a small amount of metal or if your project is small, then an open-top crucible would be better for your needs.