JB-TS6 Molten Iron Quality Thermal Analyzer

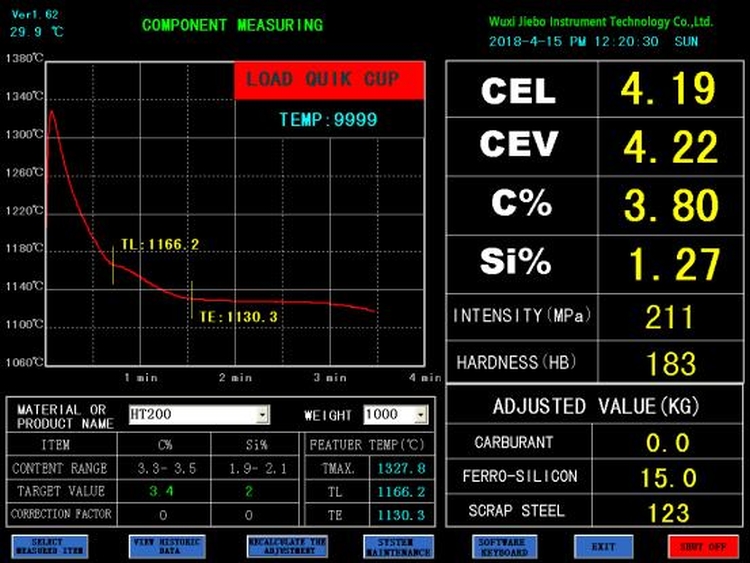

Component measuring

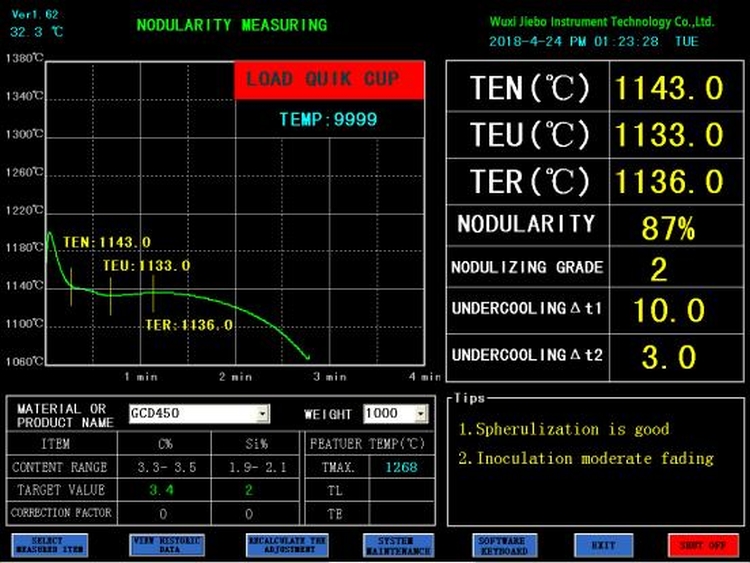

Nodular measuring for ductile molten iron

Technical Parameters:

| Specifications | Host | Industrial computer | Operating temperature | 0~40℃ | |

| Monitor | 15 inch LCD monitor | Relative humidity requirement | <90% | ||

| Power | AC 100/220V 50/60Hz | Power consumption | 40W | ||

| Dimension | 410×340×150mm

|

Weight | 8 kg | ||

| Functions | Measuring | CEL, C%, Si%, Nodular, Tensile strength, Hardness, Undercooling etc. | |||

| Adjustment Calculation | After the measurement is completed, the adjustment amount of the alloy is automatically calculated according to the preset material target value and the weight of the molten iron; the user can also temporarily modified the target value of the material and the weight of the molten iron to recalculate the adjusted addition amount of the alloy. | ||||

| Data storage | According to the timing measurements, data of results can be recorded more than 5000 times. | ||||

| Data output | By USB or RJ45 interface. | ||||

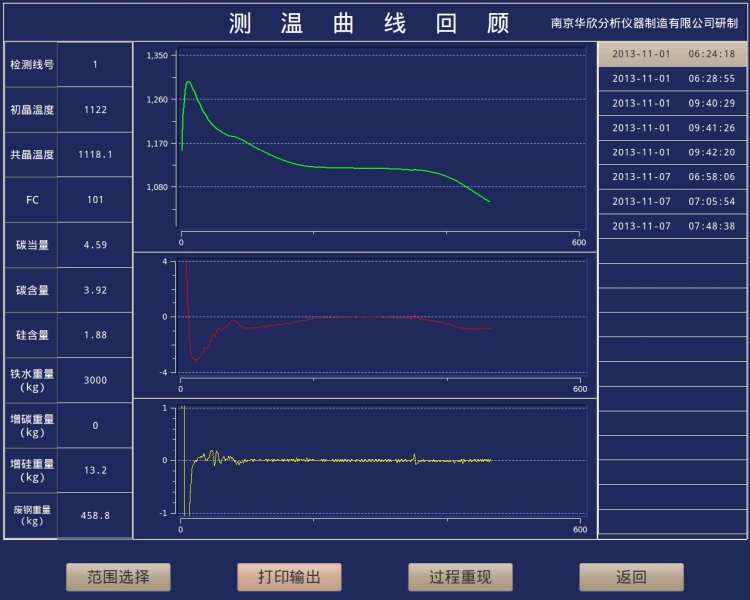

| View Historical Record | View historical measurement data, cooling curve etc. | ||||

| Measuring Range and Accuracy | Measuring item | Measuring range | Measurement accuracy | ||

| Resolution | 0.1℃(0-1372℃) | 0.1%F.S | |||

| Carbon equivalent | 2.50%~4.80% | ±0.08% | |||

| Content of Carbon(C%)

|

2.30%~4.20% | ±0.05% | |||

|

Content of Silicon(Si%) |

0.60%~3.80% | ±0.10% | |||

| Nodular | 60%~99% | ±5% | |||

| Tensile Strength | 150~400MPa | ±10MPa | |||

| Hardness | 100~300HB | ±10 HB | |||