Induction Melting Furnace- The Best Way to Melt Steel Without a Traditional Blast Furnace

What is an Induction Melting Furnace?

The induction furnace is a type of furnace that can be used in the production of steel. It is a type of electric furnace that uses induction to heat up the material to be melted.

An induction melting furnace is an electric-powered device that produces steel by heating material to be melted in an electromagnetic field. This process does not require any fuel, and it has a high level of efficiency when compared with other types of furnaces.

How Does an Induction Melting Furnance Work?

An induction melting furnace is a type of melting furnace that uses induction heating to heat up the metal. It’s a form of electric resistance heating. The furnace consists of an insulated container in which the metal is heated by an induced alternating current.

The induction melting furnace is one of the most commonly used furnaces in industry, and it has a number of advantages over other types of furnaces. It can melt metals that are not very conductive, such as aluminum or copper, and it can also melt non-metallic materials like glass or ceramics.

Why Invest in an Induction Melting Furnace over Traditional Blast Furnaces?

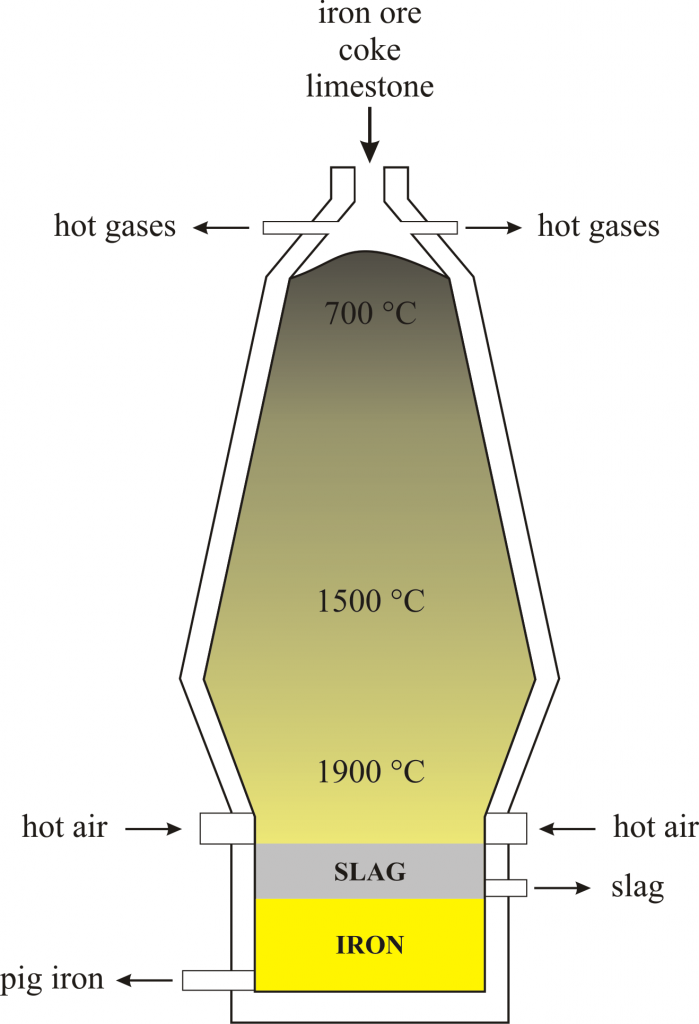

Blast furnace is a traditional technology that has been around for centuries. It was the first industrial process to produce iron and steel. But the induction melter furnace is a new technology that is more efficient and environmentally friendly and it can be used to produce all kinds of metals, not just iron.

The main advantage of an induction melting furnace over a blast furnace is that it has significantly lower emissions. This means that it does not pollute the air as much as a blast furnace does, which makes it more environmentally friendly.

How Much Does it Cost to Run an Induction Melting Furnace?

The cost of running a blast furnace is dependent on the type of furnace, and the fuel used. The cost of operating a blast furnace can also be influenced by the number and size of furnaces needed to meet production demands.

A typical induction melting furnace can cost up to $4 million for a new installation. For example, an induction melting furnace at a steel plant in China costs about $2 million for each ton per hour (tph) unit.

What is the Future of the Iron Industry and Where Will it Be Headed in the Next Decade?

The future of the iron industry is not as bleak as many people think. It is set to undergo a “revolution” in the next decade and it will be driven by new technologies that are being developed.

The iron industry has been around for more than two centuries and has played an important role in the development of modern society. With new technologies, it will be able to serve its purpose better and continue to grow in the future.