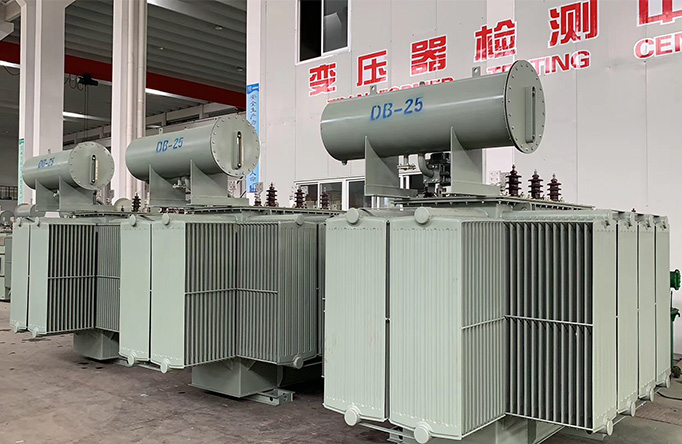

1.Type: ZPS-2250KVA/10KV/0.5KV

2.Rated capacity: net side S1=2250KVA valve side S2=2250KVA

3.Network side voltage: U1=10KV I1=129.9A Three-phase, 50 Hz.

4.Valve side no-load voltage: U2=500V,Valve side load current: I2=2598.2A

5.Connection group: Dyn11

6.Cooling method: ONAN (oil immersed from cold), using 45# transformer oil.

7.Pressure regulation mode: 5 grade, no excitation manual ± 2.5% voltage regulation

8.Impedance voltage: Z75 ° C = 6%

9.Insulation class: Class A.

10.Installation method: indoor type.

11.Outlet mode: High pressure enters the upper part of 3 porcelain bottles to form a straight line; the upper part of the low pressure porcelain bottle is out of line, and 4 porcelain bottles are lined up.

12.Internal structure: The coil adopts a cylinder and a cake structure, and has strong resistance to short circuit.

13.Working mode: It is used together with 6 pulse wave rectification system.

14.Protection: heavy gas trip, light gas alarm, over pressure release and high oil temperature alarm.

15.The transformer is equipped with a junction box in which all protective wiring is integrated.