Feeding Car:

Your current browser version is too low, in order to bring you a better browsing effect, please use a higher version browser

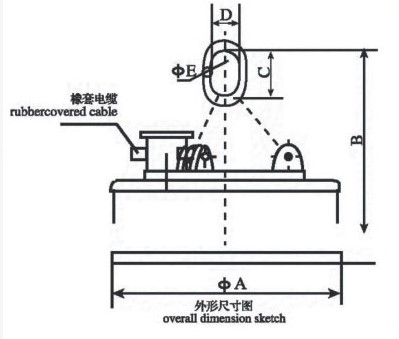

| Model | Cold-State Power

(KW) |

Current A Cold/Hot State | Overall Dimension(mm) | Weight (KG) | Lifting Capacity(kg) | ||||||

| A | c | F | E | G |

Steel Ball |

Casting Ingot | Turnings | ||||

| MW5-50L/1 | 2.6 | 11.8/7.7 | 500 | 700 | 160 | 90 | 25 | 220 | 1200 | 220/130 | 80/65 |

| MW5-60L/1 | 3.0 | 13.6/*8.9 | 600 | 750 | 160 | 90 | 25 | 340 | 2000 | 290/170 | 95/80 |

| MW5-70L/1 | 3.3 | 15/9.8 | 700 | 800 | 160 | 90 | 30 | 490 | 2500 | 380/200 | 120/100 |

| MW5-80L/1 | 4.0 | 18/12 | 800 | 800 | 160 | 90 | 30 | 620 | 3000 | 480/250 | 150/130 |

| MW5-90L/1 | 5.9 | 26.8/17.5 | 900 | 1090 | 200 | 125 | 40 | 800 | 4500 | 600/400 | 250/200 |

| MW5-110L/1 | 7.7 | 35/22.8 | 1100 | 1140 | 220 | 150 | 45 | 1350 | 6500 | 1000/800 | 450/400 |

| MW5-120L/1 | 10 | 45.5/29.5 | 1200 | 1100 | 220 | 150 | 45 | 1700 | 7500 | 1300/1000 | 650/500 |

| MW5-130L/1 | 12 | 54.5/35.5 | 1300 | 1240 | 250 | 175 | 50 | 2010 | 8500 | 1400/1100 | 700/600 |

| MW5-150L/1 | 15.6 | 70.9/46.1 | 1500 | 1250 | 350 | 210 | 60 | 2830 | 11000 | 1900/1500 | 1100/900 |

| MW5-165L/1 | 16.5 | 75/48.8 | 1650 | 1590 | 370 | 230 | 75 | 3200 | 12500 | 2300/1800 | 1300/1100 |

| MW5-180L/1 | 22.5 | 102.3/66.5 | 1800 | 1490 | 370 | 230 | 75 | 4230 | 14500 | 2750/2100 | 1600/1350 |

| MW5210L/1 | 28.4 | 129/84 | 2100 | 1860 | 400 | 250 | 80 | 7000 | 21000 | 3500/2800 | 2200/1850 |

| MW5-240L/1 | 33.9 | 154/100 | 2400 | 2020 | 450 | 280 | 90 | 9000 | 26000 | 4800/3800 | 2850/2250 |

| MW5-260L/1 | 35.6 | 162/105 | 2600 | 2100 | 450 | 280 | 90 | 10100 | 30000 | 6100/4900 | 3600/3850 |

| MW5-280L/1 | 39 | 178/116 | 2800 | 2700 | 500 | 300 | 100 | 12450 | 34000 | 7100/5700 | 4450/3400 |

| MW5-3OOL/1 | 41.6 | 189/123 | 3000 | 2300 | 500 | 300 | 100 | 14980 | 39000 | 8350/6700 | 5250/4100 |

Electric furnace charging car is a vibration feeding device specially designed and developed for melting electric furnace. The car adopts the vibration feeding method, which is convenient to use, stable feeding, can minimize the impact of the material block on the furnace body, and the feeding is more in line with the process requirements.

According to the different walking directions, the electric furnace feeding vehicle can be divided into two types: one-way straight travel and two-way straight travel. One-way straight travel, each electric furnace is equipped with a feeding car. Two-way straight travel, one feeding car can meet the feeding needs of multiple electric furnaces, and the feeding car can move horizontally and vertically.

| Feeding Car capacity | M³ | 3 | 5 | 7 |

| Applicable electric furnace capacity | T | 3 | 5 | 10 |

| Feeding speed | T/Min | 1.5(Iron) | 2(Iron) | 2 |

| Walking speed | M/Min | 20(Adjust) | 20(Adjust) | 20 |

| Walking motor | KW | 1.5 | 1.5 | 2.2 |

| Vibration motor | KW | 2×2.2 | 2×3.7 | 2×5.5 |

| Noise | dB | <75 | <75 | <75 |

| Dimensions mm (adjustable according to customer site) | 4200×1900×1800 | 5900×2300×2000 | 6100×2300×2400 | |

| Gauge mm (adjustable according to customer site) | 1500 | 1800 | 2000 |