Ladle

Huaxin specialize in the design,research,manufacture and sale of the Water Cooling equipment. Main products: Closed Cooling Water, Transverse Flow Cooling Tower, Countercurrent Tower, Refrigerating Machine and Evaporative Machine etc.

Company has the extensive products,we can also provide other relative accessories and technical consultation at the same time.Keeping improving is our constant purpose, every step we can do better from the selection of the raw material to the research and manufacture of a series products.We consider more for our clients

Company has the extensive products,we can also provide other relative accessories and technical consultation at the same time.Keeping improving is our constant purpose, every step we can do better from the selection of the raw material to the research and manufacture of a series products.We consider more for our clients

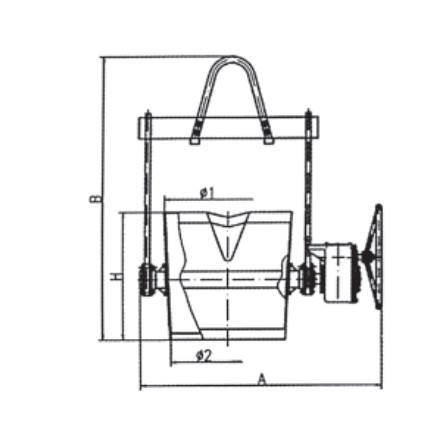

Tea Pot Ladle Product introduction and advantages

- There is a retaining wall at the mouth of the bag. The slag floating on the molten iron is blocked during pouring.

- The molten iron can be poured into the casting mold through the channel under the retaining wall smoothly, which has a good filtering effect.

- The clad steel plate is thick, and the bottom of the clad is combined with taper and welding ribs, which not only prolongs the service life, but also ensures safety.

- Self-aligning bearings are installed between the two shafts and the boom, which is consistent.

- The package body, suspension rod and reduction gearbox are equipped with chain clamping plates, which can be locked at any time, and are equipped with turbo worm reducer.

- It is divided into manual and electric: manual operation is convenient; electric is for motor rotation, safe and labor-saving; two-way Technical Parameters rotation, easy operation.

Tea Pot Ladle Technical Parameters

| specification | φ1 | H | B | A |

| CB-0.5 | 585 | 715 | 1332 | 1375 |

| CB-1 | 730 | 900 | 1491 | 1780 |

| CB-2 | 880 | 1080 | 1711 | 2046 |

| CB-3 | 1060 | 1230 | 1856 | 2198 |

| CB-4 | 1150 | 1320 | 2056 | 2450 |

| CB-5 | 1230 | 1420 | 2254 | 2662 |

| CB-8 | 1450 | 1580 | 3345 | 2120 |

| CB-10 | 1580 | 1820 | 3630 | 2280 |

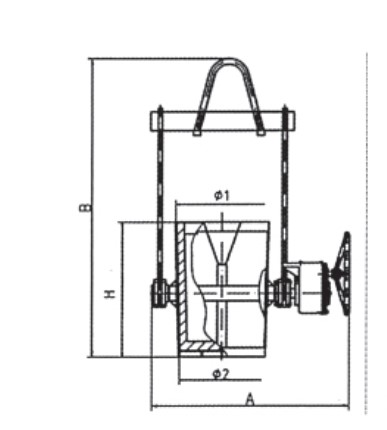

Ladle of Spheroidization Purpose

The hot metal ladle is used for casting in the casting workshop. After receiving the molten iron in front of the furnace, the truck is transported to the casting place for casting.

Ladle of Spheroidization Features

- The slewing center has been reasonably selected, which is convenient to operate, and can basically be repeated after pouring.

- Adopt double worm gear pair transmission. Although the manufacturing requirements are high, the transmission is flexible and bidirectional inverse.

- The forgings are made of forgings, which are more reliable and safer than steel plate welded parts.

- The clad steel plate is thick, and the bottom structure adopts the triple protection of taper, bottom hoop and welding risk, which extends the service life and ensures the safety of the operator.

- The main body and the boom, the reduction box and the hand wheel are all equipped with chain-locking plates that can be locked at any time.

- Self-aligning bearings are installed on both trunnions and hangers to ensure good consistency.

Ladle of Spheroidization Technical Parameters

| specification | φ1 | φ2 | H | A | B |

| TB-0.5T | 592 | 532 | 608 | 1120 | 1248 |

| TB-0.75T | 660 | 593 | 670 | 1192 | 1335 |

| TB-1T | 715 | 643 | 718 | 1245 | 1518 |

| TB-1.5T | 830 | 746 | 840 | 1415 | 1728 |

| TB-2T | 892 | 800 | 921 | 1430 | 1855 |

| TB-3T | 1026 | 925 | 1025 | 1630 | 2020 |

| TB-5T | 1230 | 1106 | 1238 | 2040 | 2458 |

| TB-7T | 1345 | 1208 | 1370 | 2400 | 2770 |

| TB-8T | 1420 | 1278 | 1425 | 2425 | 2850 |

| TB-10T | 1542 | 1388 | 1546 | 2610 | 3106 |

| TB-12T | 1640 | 1476 | 1672 | 2650 | 3192 |

| TB-15T | 1765 | 1586 | 1785 | 2780 | 3290 |

| TB-20T | 1930 | 1736 | 1973 | 3072 | 3636 |

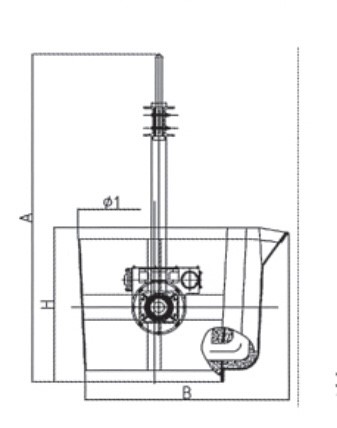

Ladle of Steel Specifications of Ladle:

1) Cypriot Leveraged,

2) Sliding Outlet

Ladle of Steel Technical Parameters

| Ladle specification (t) | Barrel diameter (mm) |

Barrel height (mm) |

Dimensions of ladle Length × Width × Height (mm) |

Total Weight (t) |

| GB-8 | 1550 | 1675 | 1960×1960×3335 | 12.4 |

| GB-10 | 1733 | 1765 | 2132×2132×3425 | 15.5 |

| GB-12 | 1810 | 1850 | 2230×2230×3630 | 19.5 |

| GB-15 | 1925 | 1975 | 2340×2340×3775 | 23 |

| GB-20 | 2080 | 2141 | 2486×2480×4102 | 31 |

| GB-25 | 2206 | 2285 | 2622×2620×4385 | 40 |

| GB-30 | 2316 | 2408 | 2760×2650×4680 | 46 |

| GB-35 | 2420 | 2518 | 2880×2750×4760 | 52 |

| GB-40 | 2528 | 2616 | 3056×2800×4860 | 58 |

| GB-45 | 2591 | 2710 | 3120×2820×5180 | 62 |

| GB-50 | 2650 | 2830 | 3280×2860×5260 | 71 |

| GB-60 | 2808 | 2945 | 3450×3010×5400 | 79 |

| GB-70 | 2845 | 2983 | 3500×3050×5560 | 95 |

| GB-90 | 3160 | 3400 | 3850×3360×5880 | 120 |

| GB-105 | 3288 | 3467 | 3980×3490×5950 | 136 |

| GB-160 | 3730 | 3953 | 4600×3950×6600 | 210 |

| GB-200 | 4060 | 4250 | 4841×4560×7432 | 260 |

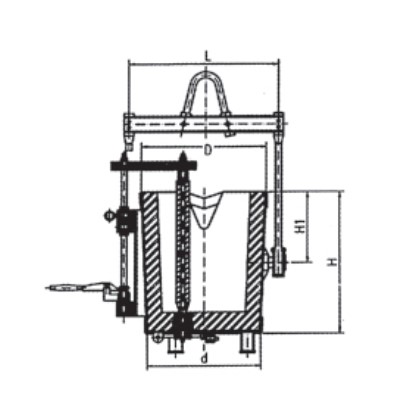

Ladle of Iron Technical Parameters

|

specification |

φ1 | φ2 | H | A | B |

| QB-0.5T | 570 | 525 | 825 | 1110 | 1450 |

| QB-0.75T | 650 | 598 | 943 | 1185 | 1605 |

| QB-1T | 688 | 635 | 990 | 1230 | 1745 |

| QB-1.5T | 780 | 718 | 1132 | 1390 | 1962 |

| QB-2T | 860 | 762 | 1250 | 1415 | 2168 |

| QB-2.5T | 910 | 838 | 1320 | 1560 | 2472 |

| QB-3T | 980 | 902 | 1422 | 1620 | 2349 |

| QB-5T | 1150 | 1058 | 1668 | 2010 | 2815 |

| QB-8T | 1320 | 1215 | 1915 | 2386 | 3345 |

| QB-10T | 1630 | 1316 | 2075 | 2580 | 3635 |

| QB-12T | 1550 | 1436 | 2080 | 2620 | 3650 |

| QB-15T | 1680 | 1563 | 2130 | 2738 | 3780 |

| QB-20T | 1812 | 1618 | 2208 | 2732 | 3714 |