Heat Treatment Furnace

Principle of induction heating

Induction heating is a non-contact operation, which consists in influencing the conductors, which are metal workpieces, of high-frequency currents induced by an alternating magnetic field.

the workpiece is placed in an inductor, which with the help of a converter creates around itself a powerful electromagnetic field, which induces eddy currents in the workpiece, which it also warms up.

Induction heating applications

Usage:

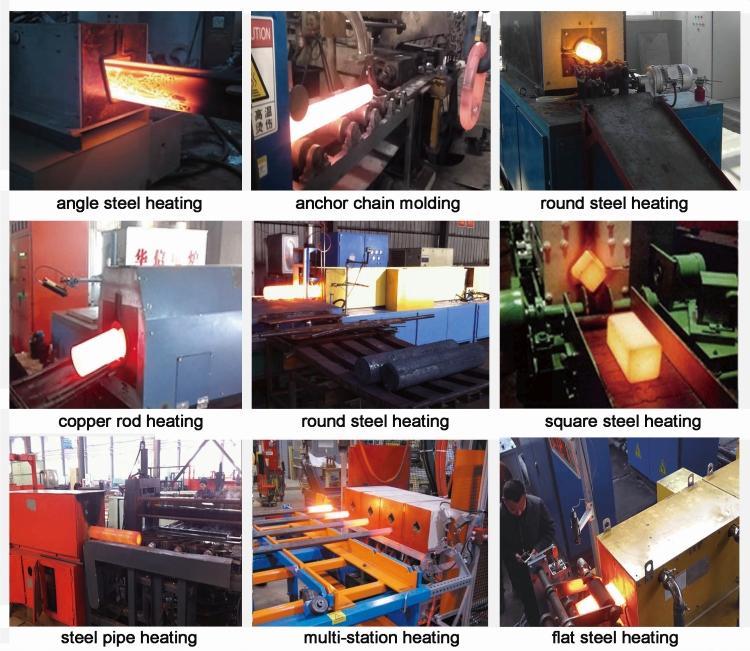

Heating before forging: used in gear, gear ring, axle shaft connecting rod, bearing, shackle, and rigging heating before forging.

Heating online: corrosion prevention spraying of pipes, bar blue brittleness blanking, and steel wire/tubes tempering online.

Local heating: u-shape bolts bending, roller thermal assembling, steel tube bending heating process

Induction heating site

Characters and Advantages:

1) Produce process is easy to operate, charge in and discharge flexibly, high degree of automation, realize produce on line.

2) Fast speed of work piece heating, less oxidization or decarburization, high efficiency, and quality forging piece.

3) High control accuracy of work piece length, speed, and temperature.

4) Good heat uniformity of work piece, small temperature difference on core surface, high control accuracy.

5) Integration design of inductor and furnace body, quick-change connector for different inductors, easy to change and replace.

6) Omni energy conservation optimal design, low energy consumption, high efficiency, lower cost than coal furnace.

7) Fit environmental protection requirement standard, little pollution, and reduce labor intensity of workers.

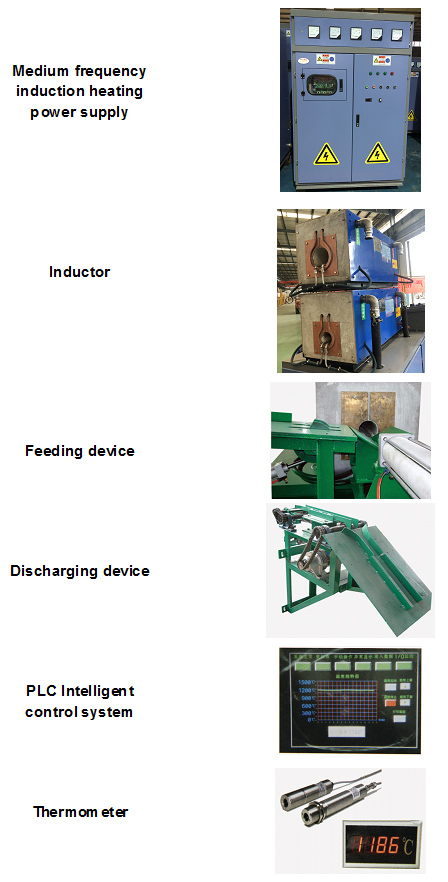

Induction heating equipment configuration

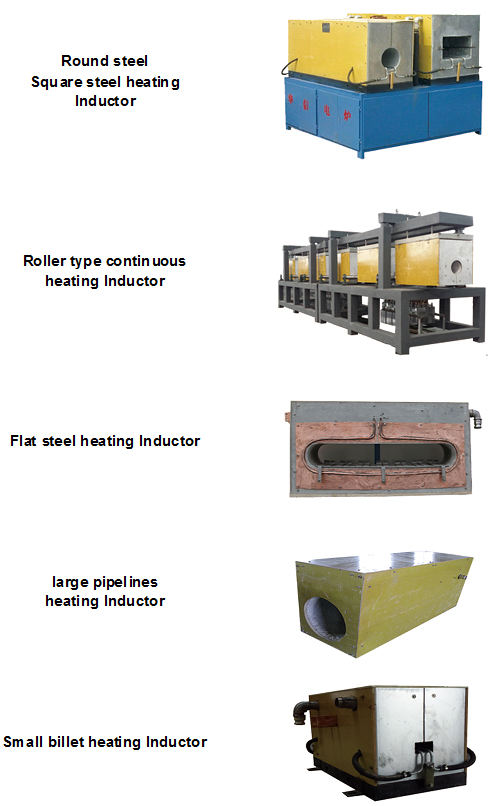

Different types of Inductors