C. Furnace Parts:

1.Furnace Parts:

The mechanical parts of the MF furnace consisted of furnace pot,water power introduced into the system, titling device and other parts.

2.Furnace Ports:

Furnace port including furnace shell, induction coil etc.

3Furnace Shell

Furnace shell made of cast aluminum furnace shell halves connected together, with good rigidity, compact structure, easy maintenance, etc., the rotary bearing hole once processed, to ensure concentricity of the furnace shell and rotary bearing tilting furnace process will not be deformed due to misalignment.

Induction Coil Design Principle:

Coil is the heart of induction furnace, induction coils will produce a strong magnet field under the action of the electric current. Coil design is very important since Coil is the key part of the conversion between Electrical energy and heat. 99.99% red copper.

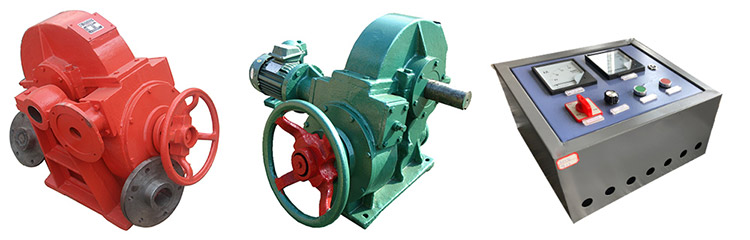

Reducer Features and Applications:

Reducer mainly by the transmission parts (gears or worm), shafts, bearings, housing and accessories formed. Is divided into two kinds of manual and electric, our company is the use of electric reducer.

Applied to the furnace shell furnace tilting, and compared to traditional manual gearbox, more secure and reliable, the speed proportioned.

Tilting Control Box:

Tilting control box is in front of the furnace body, used to control the tilting (in the range of 0 ~ 95 degrees). It uses gear and steering operation, reliable, smooth, non-impact and creeping phenomenon, can stay in any position.

Water Cooling Cables:

Water-cooled cables made of high quality material T2 multi-strand copper wire,outside is a high- strength fire-resistant rubber tube,connector cold forming,good contact and tensile strength

Aluminum-Shell-Melting-Furance-s.jpg)