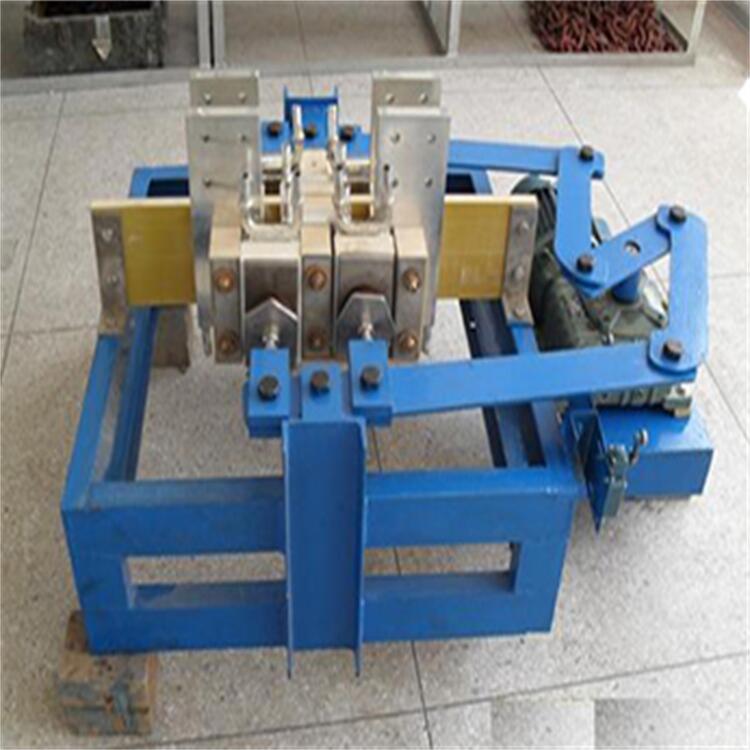

Furnace change switch

The medium frequency smelting furnace is generally configured with one electric furnace and two furnaces, that is, one set of furnace body is used for smelting and one set of furnace body is standby. The use of furnace change switch can avoid the frequent reverse connection of the output copper bar of the main circuit, improve the work efficiency, reduce the labor intensity of workers and ensure safety.

I Medium frequency smelting furnace change-over switch

The traditional medium frequency furnace is replaced by manually removing the connecting cable from one furnace body and then connecting it to another furnace body. Such frequent disassembly and assembly increases the labor intensity of workers, and manual disassembly and assembly. Sometimes, due to the mistakes of workers, the connecting bolts are not tightened during assembly, and the phenomenon of “ignition” occurs when opening the furnace, which is bound to damage the thyristor of medium frequency power supply. Therefore, the switch came into being. The basic requirements for the reversing switch are safety and reliability, long service life and convenient operation.

II Classification of medium frequency smelting furnace change-over switch:

The furnace change switch is divided into manual and automatic: manual switching depends on manual moving of water-cooled copper bar. Automatic switching depends on the hydraulic system. When changing the furnace, just press the furnace change switch button every time.

III Switching principle of medium frequency smelting furnace:

The medium frequency smelting furnace change-over switch is used to switch two furnace bodies. The furnace change-over switch is driven by the motor. When changing the furnace, it only needs to be operated on the operation console in front of the furnace. The position of the furnace change-over switch has self-locking function. The control circuit of the furnace change switch is interlocked with the power supply. The power supply can be started only after ensuring that the furnace change is in place. Confirm that one power supply is connected to only one furnace body before starting the power supply. The furnace can be changed only after the power supply is stopped.

4、 Advantages of medium frequency smelting furnace change-over switch:

1. It eliminates the work caused by frequent replacement of water-cooling cable or furnace reversing switch, and reduces the labor intensity of workers.

2. The furnace change switch changes the plug-in contact of the electrode plate of the original power system switch to the compression contact, the electrode plate is free of wear, which greatly improves the service life, the contact surface of the conductive electrode plate is large, the pressing force, and the mechanical positioning is accurate and reliable.

3. The furnace changing switch has the advantages of accurate positioning, high reliability, long service life, low price and is suitable for China’s national conditions, which increases the safety of medium frequency smelting furnace switching.

4. The surface of the conductive plate is plated with silver, which reduces the surface oxidation, improves the conductivity and has a beautiful appearance. The welded water-cooling pipe of similar foreign water-cooling switch is changed into perforated water cooling, which improves the cooling effect and appearance quality.

5. Equipped with water separator and water collecting tank, it is very convenient for users to connect the cooling water circuit.

5、 Characteristics of medium frequency smelting furnace change-over switch:

1. High current; 2. Bipolar double throw; 3. Water cooling; 4. Manual; 5. Therefore, all copper materials are silver plated or tin plated, which is not easy to ignite; 6. The copper pipe on the copper bar is drawn integrally (not welded), so there is no water leakage.