Features and introduction of series one with two circuit

1. The inverter uses phase control to adjust the output power of the intermediate frequency power supply, instead of adjusting the output power by the rectifier bridge. Therefore, during the smelting process, a constant power output can be obtained to shorten the smelting time, save energy, and improve economic benefits.

2. In the whole process of operation, the device has a very high power factor. Because the rectifier circuit is always full voltage output during operation, that is, the control angle α=0°. And the harmonic interference to the power grid is reduced to a minimum.

3. Has excellent starting performance. This device uses series inverter technology, so it can start reliably under any load conditions, start smoothly, and has no impact on the grid, and the start success rate is 100%.

4. efficient. The series inverter adopts a half-bridge circuit, the number of main circuit components is relatively reduced, and the power factor is very high, so it has a higher efficiency.

5. It has a complete protection and operation monitoring system.

6. Has a complete monitoring system

The working temperature of the inverter and filter capacitor is monitored by a temperature switch meter. Once the cooling water temperature exceeds the set value or there is a water circuit failure, an alarm will be issued and the power supply will be cut off.

Pressure and temperature sensor devices are used to monitor the capacitor. Once the capacitor leaks or the temperature is too high, an alarm will be issued and the power supply will be cut off.

The power supply cooling water input is controlled by a water pressure relay, and the cooling water output has a temperature switch meter to monitor undervoltage. If over temperature, an alarm will be issued and the power supply will be cut off.

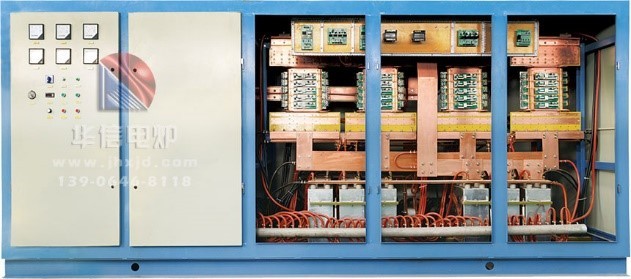

Equipped with output voltmeter, output power meter, working frequency meter, input ammeter, input voltmeter, DC voltmeter, DC ammeter, the control panel is equipped with a lack of phase display and inverter work display. Two furnaces can display intermediate frequency voltage, power and working frequency respectively.

A line circuit breaker is installed in the electrical control cabinet, which is a visible disconnection point for the power supply line isolation switch and the knife switch, with short-circuit protection, grounding trip protection and phase loss protection, fuse, etc.

The door of the electrical cabinet is interlocked with the power-off circuit, and the main power supply is cut off when the door of the electrical cabinet is opened. The lighting lamp is on, the control power supply has electricity for inspection and maintenance, and a spare socket is provided.

The original design of the electrical appliance is reasonable, the discharge is neat, and the maintenance and replacement of parts are convenient and quick. The major heating elements and copper bars are all equipped with reasonable water cooling as required.

Set up a complete protection system, such as: use sensors to take signals for incoming line current, voltage, tank current, and voltage, and provide double closed-loop digital circuits for current limiting, voltage limiting, and overcurrent and overvoltage repeated protections, including water temperature and water pressure Protection and so on. Both KK SCR and KP SCR have self-turn-off time protection.