Basic characteristics of medium frequency furnace

In metal smelting, the most commonly used is the medium frequency melting furnace. It is composed of an intermediate frequency power supply and an intermediate frequency furnace body, and is equipped with a hydraulic system, a dust removal system, a capacitor cabinet and a water-cooled cable. The role is that for various metal smelting, it should have the following basic characteristics:

- The intermediate frequency melting furnace has high melting efficiency, which basically guarantees one furnace of molten steel every hour. The power saving effect of the smelting furnace is good, and the power consumption per ton should be about 600 degrees. The intermediate frequency power supply and furnace body have compact structure and strong overload capacity;

- Due to the fast heating speed of the intermediate frequency smelting furnace, the overall heating temperature is uniform, the burning loss is small, and the metal composition is uniform;

- The intermediate frequency smelting furnace has less magnetic leakage, low temperature around the furnace body, less smoke and dust, and good working environment;

- The intermediate frequency smelting furnace has simple production and operation, low labor height, low personnel input, and reliable smelting operation;

- The induction coil of the intermediate frequency smelting furnace is equipped with water-cooled coils to make the furnace lining evenly heated and prolong the service life of the furnace lining;

- The induction coil of the intermediate frequency smelting furnace is equipped with short-circuit loops up and down to effectively shield the magnetic flux leakage at both ends of the line;

- The long arc yoke shields the magnetic flux leakage and reduces the external magnetic resistance. It has the function of shielding the magnetic leakage around the coil. The cross section of the yoke is seamlessly attached to the inner wall of the arc to increase the effective magnetic permeability area and make the bottom The circle is well supported. The unique positive and negative coils greatly improve the efficiency of the system.

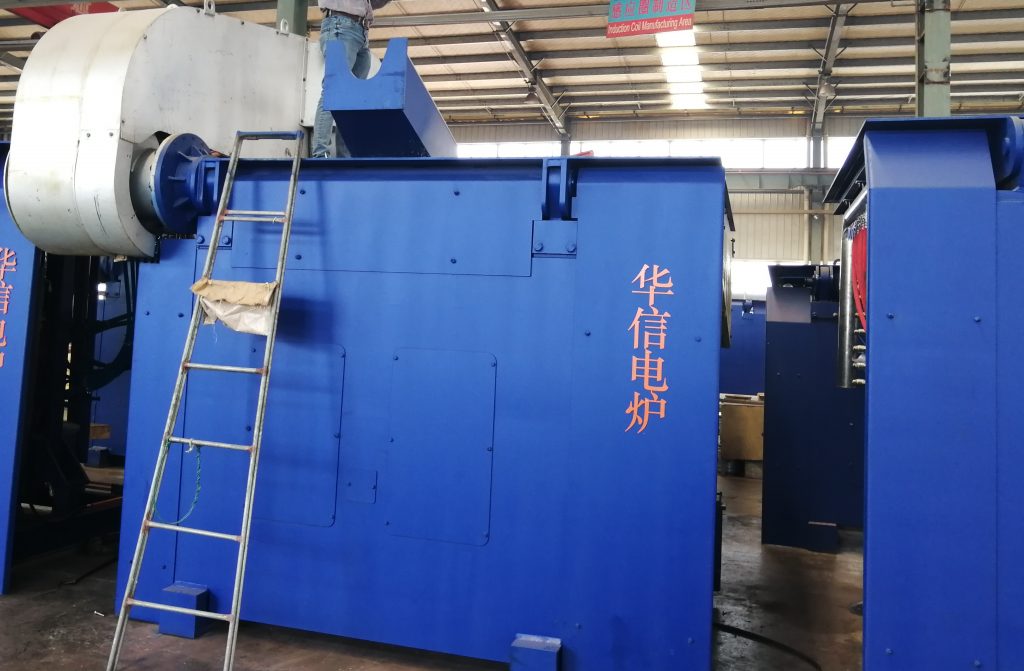

Shandong Huaxin Electric Furnace Co., Ltd. specializes in the production: intermediate frequency heating furnace, intermediate frequency melting furnace, intermediate frequency electric furnace, one-to-two series resonance intermediate frequency furnace, induction heating furnace, induction heating equipment, intermediate frequency induction heating furnace, induction heating power supply, forging heating furnace, With advanced technology, high-quality products and excellent service, we are dedicated to serving customers at home and abroad with heat treatment equipment such as tempering equipment, intermediate frequency induction heating, intermediate frequency heat treatment and tempering production lines.

Huaxin electric furnace products and equipment are widely used in the foundry industry, forging industry, heat treatment industry, petroleum machinery industry, mining and coal mining machinery industry, steel pipe, impermeable steel industry, machinery, thermal assembly processing industry, metallurgical industry, automobile and auto parts , Construction machinery and other industries.