The Structure and Principle of the Induction Coil

The induction coil is a crucial component in medium frequency furnace systems. It plays a vital role in the heating process by generating a strong magnetic field that induces eddy currents in the workpiece. This article will explore the structure, principle, and design considerations of the induction coil.

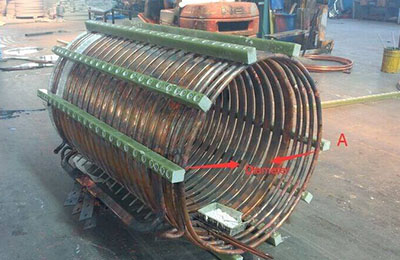

induction coil of electric furnace

Structure of the Induction Coil:

The induction coil typically consists of a copper conductor wound in a helical shape. The number of turns and the diameter of the coil can vary depending on the specific application. The coil is often enclosed in a protective housing to prevent damage and ensure efficient energy transfer.

Principle of the Induction Coil:

The induction coil operates on the principle of electromagnetic induction. When an alternating current (AC) flows through the coil, it creates a rapidly changing magnetic field around it. This magnetic field induces eddy currents in any nearby conductive material, such as the workpiece.

The induced eddy currents generate heat due to the resistance of the material. As a result, the workpiece quickly heats up. The intensity of the magnetic field and the rate of heat generation depend on various factors, including the coil’s design, the frequency of the current, and the properties of the workpiece.

Design Considerations of the Induction Coil:

Several factors need to be considered when designing the induction coil:

1. Coil Geometry: The coil’s geometry, including the number of turns and the diameter, affects the efficiency of energy transfer. A higher number of turns increases the magnetic field intensity but may lead to reduced energy efficiency. The diameter of the coil should be optimized to provide the desired heating uniformity.

2. Coil Material: Copper is commonly used due to its excellent electrical conductivity. It allows for efficient current flow and minimizes energy losses. The coil material should also have good heat resistance to withstand the high temperatures generated during operation.

3. Cooling System: As the induction coil operates, it generates heat that needs to be dissipated to prevent overheating. A cooling system, such as water circulation, is often integrated into the coil design to maintain optimal operating temperatures.

4. Electrical Connections: The induction coil requires electrical connections to the power supply. Proper insulation and secure connections are essential to ensure safe and reliable operation.

Conclusion:

The induction coil is a critical component in medium frequency furnace systems. Its structure, principle, and design considerations significantly impact the efficiency and effectiveness of the heating process. By understanding the coil’s role and optimizing its design, engineers can enhance the performance of induction heating systems in various industrial applications.