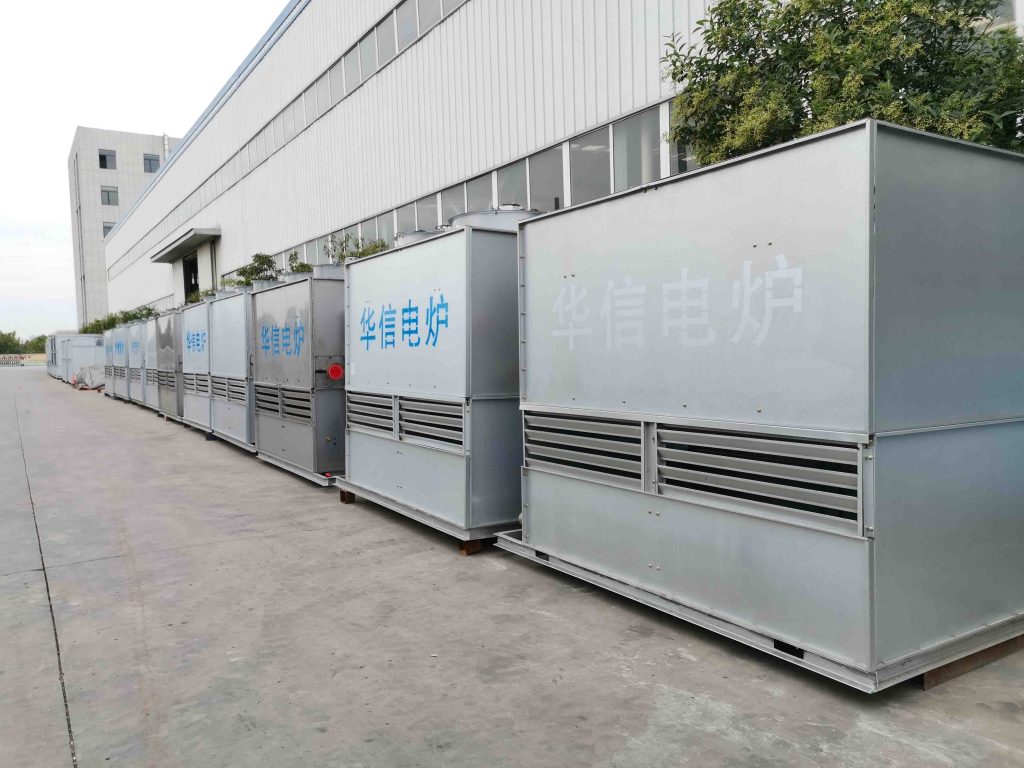

The cooling tower for induction melting furnace

The cooling tower for induction furnace is a closed cooling tower that reduces the temperature of the cooling water in the intermediate frequency induction electric furnace to meet the cooling requirements of the electric furnace. The thyristors, capacitors, reactors, induction coils, and water cables of the induction furnace have been working for a long time, causing the temperature of the cooling water to rise. The 40-50 degree high temperature water in the furnace is cooled and processed to a normal temperature lower than 35 degrees.

One. Cooling tower model for induction furnace

Cooling towers for induction furnaces are divided into: circular general (DBNL) type induction furnace cooling towers, and industrial type (GBNL) induction furnace cooling towers. Circular general intermediate frequency furnace cooling towers are suitable for processing 40-50 degrees of hot water. Cooling towers for industrial induction furnaces are suitable for processing hot water at 50-60 degrees Celsius. The ordinary circular shape is widely used in small foundries and steel mills, and the industrial type is widely used in large casting and steel mills.

Two. The proportional coefficient of cooling tower cooling effect and exhaust air volume for induction furnace

After years of trial and error, Huaxin Electric Furnace finally calculated that the ratio coefficient between the cooling effect and the exhaust device of the cold water tower of the intermediate frequency furnace is 3. Only this coefficient can achieve a better cooling effect.

Third, the calculation method for the selection of the cooling tower for the induction furnace

Many customers only know how big their tank is, but they don’t know how big the cooling tower for induction furnace is to use to achieve good results?

For example: if you have a length of 3 meters and a width of 3 meters. A pool of 2 meters high. Its calculation formula is: the total cube of the pool is multiplied by the effect coefficient 3. The formula: (3x3x2)x3=54, then you choose a 60-ton intermediate frequency furnace cold water tower, and the induction furnace cooling tower is divided into: 20 tons, 40 Tons, 60 tons, 80 tons, 100 tons, 120 tons, 150 tons, 175 tons, 200 tons, up to 1000 tons. The tonnage here refers to the amount of water processed by the cold water tower of the intermediate frequency furnace per hour, not the induction The weight of the furnace cooling tower itself.