Intermediate frequency coreless induction melting furnace

Ⅰ. Overview of intermediate frequency coreless induction melting furnace:

High power density coreless steel shell induction melting furnace, hydraulic tilting furnace mechanism, high-strength frame structure, strong and durable, water-cooled arc yoke, fully reduce the loss of the external magnetic circuit, the optimized design of the induction coil, improve the electromagnetic conversion Rate.

Ⅱ. the characteristics of the intermediate frequency coreless induction melting furnace

1. Installation and operation are very convenient

2. Ultra-small size, light weight, movable, covering an area of less than 1 square meter;

3. 24-hour uninterrupted melting capacity;

4. Power saving and energy saving;

5. It is convenient to replace the furnace body with different weights, different materials, and different starting methods to meet various melting requirements;

6. Good heating permeability and uniform temperature

7. The intermediate frequency magnetic field has a magnetic stirring effect on the molten metal, which is conducive to uniform composition and scum

Ⅲ. Working environment of intermediate frequency coreless induction melting furnace

1. The ambient temperature is in the range of +5℃-40℃.

2. The relative temperature of the surrounding environment does not exceed 90% (25°C).

3. The altitude does not exceed 1000 meters.

4. There is no conductive dust, explosive gas or corrosive gas that can seriously damage metal and edges around the furnace body of the medium frequency induction electric furnace.

5. There is no obvious vibration and bumps.

6. The cooling water temperature is +5℃-30℃. The water hardness is not more than 8 degrees, the turbidity is not more than 5 degrees, and the pH value of the pH is in the range of 6.5-8.5.

7. The fluctuation of the three-phase power supply is not more than ±5%.

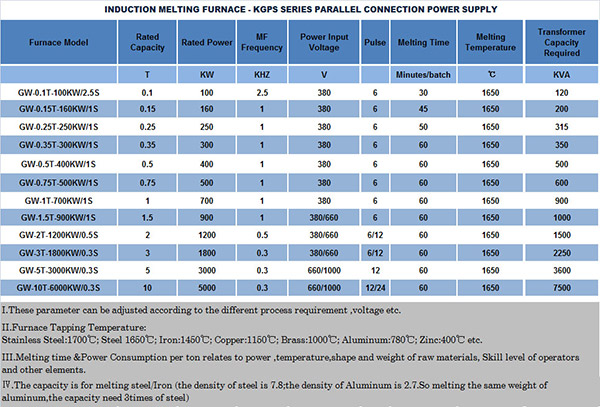

Ⅳ. Specifications and main parameters of intermediate frequency coreless induction melting furnace