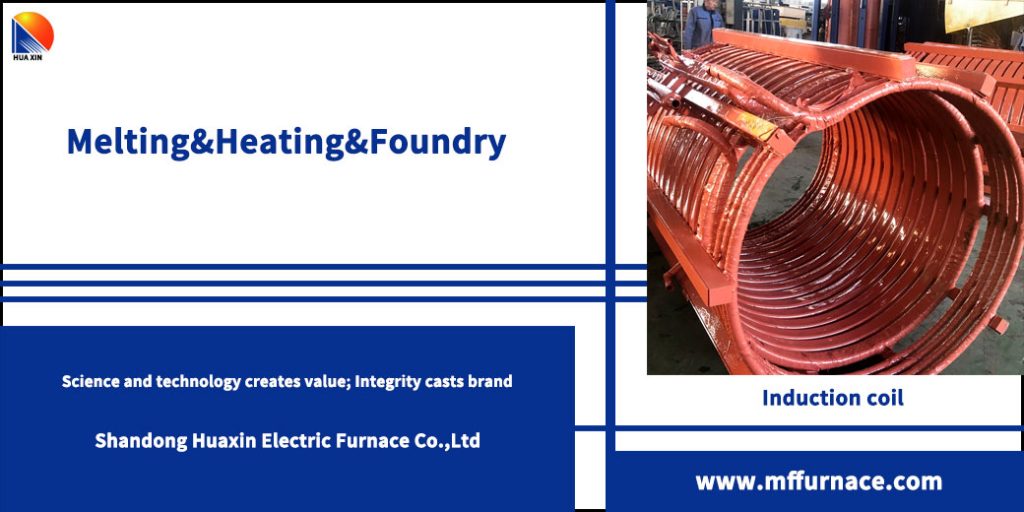

How to maintain the induction heating coil

Induction coil, I believe everyone who knows induction heating equipment knows that induction coil is an important part of induction heating equipment, and it is an indispensable part of induction heating equipment to heat the workpiece. Whether the routine maintenance of the induction coil is in place is related to the service life of the induction heating equipment, and it also determines the heating quality of the workpiece to a large extent. Therefore, it is very necessary to carry out the routine maintenance of the induction coil.

The routine maintenance of the induction coil of the induction heating equipment mainly includes visual inspection, coil compression screw, rubber tube, coil anti-corrosion joint, cooling water temperature at the coil outlet, dust removal, etc.

- Visual inspection

Check the appearance of the induction coil of the induction heating equipment, mainly to check whether the insulation part of the coil is damaged or carbonized, whether there is foreign matter attached to the surface of the coil, whether the insulating backing plate between the coils is protruding, and whether the assembly bolts of the corresponding coil are loose.

- Check the coil compression screw, visually check whether the coil compression screw is loose.

Three, rubber hose

The inspection of the rubber tube mainly includes two aspects. On the one hand, it is to check whether there is water leakage at the joint of the rubber tube; on the other hand, it is to check whether the rubber tube has cuts.

- Inspection of the anti-corrosion joint of the coil, remove the rubber hose, and check the degree of corrosion of the anti-corrosion joint at the end of the coil.

- The temperature of the cooling water at the coil outlet under the conditions of rated molten iron volume and rated power, record the larger and smaller values of the cooling water temperature of each branch of the coil.

- Dust the induction coil and blow off the dust and molten iron splashes on the surface of the coil with compressed air.