Working Principle of Aluminum Melting Furnace

Aluminum smelting furnaces plays a crucial role in the production of aluminum, a widely used metal in various industries. Understanding the working principle of these furnaces is essential to ensure efficient and safe operations. In this article, we will discuss the working principle of aluminum smelting furnaces, with a focus on the principles of induction melting furnaces.

Working Principle of Aluminum Smelting Furnace:

1. Induction Furnace

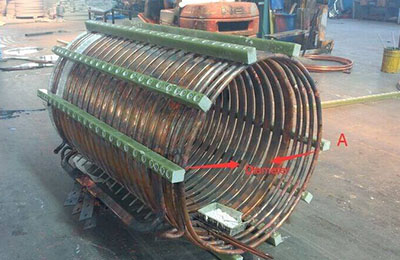

One of the commonly used types of aluminum smelting furnaces is the induction furnace. The working principle of an induction furnace involves the use of electromagnetic induction to generate heat. The furnace consists of a crucible, made of a refractory material, which holds the aluminum and acts as a container for the melting process.

2. Electromagnetic Induction

The principle of electromagnetic induction is based on Faraday’s law. When alternating current (AC) passes through a coil, it generates a magnetic field around it. This magnetic field induces eddy currents in the conductive material present within its vicinity. In the case of an induction furnace, the conductive material is the aluminum.

3. Melting Process

As the AC current passes through the coil, the magnetic field generated induces eddy currents in the aluminum. These eddy currents result in the generation of heat due to the resistance offered by the aluminum. The heat generated by these currents causes the aluminum to melt and reach its desired temperature.

4. Crucible Design

The design of the crucible is crucial for the efficient operation of the induction furnace. The crucible should have good thermal conductivity to ensure uniform heating of the aluminum. Additionally, it should be able to withstand high temperatures and resist chemical reactions with the molten aluminum.

5. Control Systems

To maintain precise control over the melting process, induction furnaces are equipped with sophisticated control systems. These systems regulate the power input, frequency, and other parameters to ensure optimal melting efficiency. The control systems also include safety features to prevent overheating or other potential hazards.

In conclusion, the working principle of an aluminum smelting furnace, particularly the induction furnace, relies on electromagnetic induction to generate heat. The induction furnace utilizes alternating current to induce eddy currents in the aluminum, resulting in the melting of the metal. Understanding the principles of induction melting furnaces is essential for the efficient and safe operation of aluminum smelting processes.