What is the Objective of Heat Treatment Furnace?

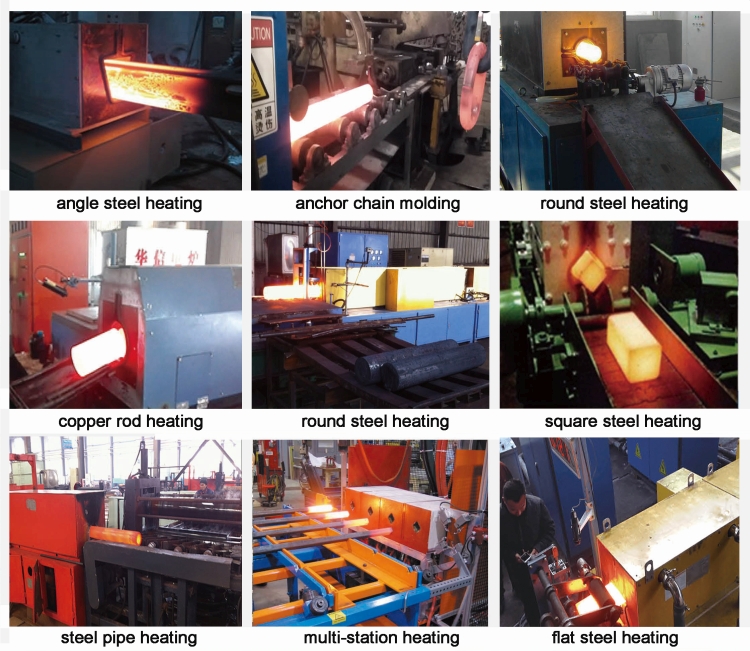

Heat treatment furnaces are essential equipment used in the manufacturing industry to modify the physical and chemical properties of materials. The objective of heat treatment furnace is to alter the microstructure of materials such as metals, alloys, and ceramics to enhance their mechanical and physical properties. Heat treatment furnaces use various heating methods such as induction heating, electric resistance heating, and gas heating to achieve the desired outcome.

Induction heating is a common method used in heat treatment furnaces. It involves the use of an electromagnetic field to heat the material quickly and uniformly. This method is useful in hardening materials such as steel, where the surface is heated to a high temperature and then quenched in water or oil to create a hard and wear-resistant surface.

Heating furnaces also use electric resistance heating, which involves passing an electric current through the material to heat it. This method is useful in annealing materials, where the material is heated to a specific temperature and then cooled slowly to reduce its hardness and increase its ductility.

The objective of heat treatment furnaces is to improve the mechanical properties of materials such as strength, toughness, and ductility. Heat treatment can also improve the material’s resistance to wear, corrosion, and fatigue. Heat treatment is a crucial process in the manufacturing industry, as it can significantly impact the quality and performance of the final product.

In conclusion, the objective of heat treatment furnaces is to modify the microstructure of materials through various heating methods such as induction heating and electric resistance heating. The ultimate goal is to improve the mechanical and physical properties of the material, making it more durable and resistant to wear and corrosion. Heat treatment is a critical process in the manufacturing industry, and the use of heat treatment furnaces is essential to achieve the desired outcome.