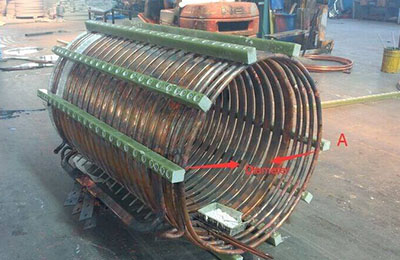

Repair method of induction coil of medium frequency electric furnace

The induction coil is a critical component of a medium frequency electric furnace. It is responsible for generating the magnetic field necessary for the induction heating process. Over time, the coil may experience wear and tear, leading to a decrease in performance. This article will discuss the repair methods for the induction coil of a medium frequency electric furnace.

1. Inspection:

Before starting the repair process, it is essential to thoroughly inspect the induction coil. Look for any visible signs of damage, such as cracks, breaks, or discoloration. Additionally, check for any loose or damaged connections.

2. Coil replacement:

If the induction coil is severely damaged or beyond repair, it may be necessary to replace it entirely. This involves removing the old coil and installing a new one. It is crucial to ensure that the replacement coil is compatible with the specific medium frequency electric furnace model.

3. Coil repair:

If the damage to the induction coil is minor, it may be possible to repair it. One common method is to weld the damaged areas using a high-quality welding machine. This process requires skilled technicians who are experienced in working with induction coils.

4. Coil reconditioning:

In some cases, the induction coil may become worn out due to prolonged use. In such situations, reconditioning the coil can help restore its performance. This involves cleaning the coil and removing any built-up dirt or debris. Additionally, the coil may need to be reshaped or repositioned to ensure optimal performance.

5. Coil insulation:

Proper insulation of the induction coil is crucial to prevent electrical leakage and ensure safe operation. If the insulation is damaged or worn out, it should be replaced. Insulation materials such as mica or ceramic can be used to re-insulate the coil.

6. Regular maintenance:

To prevent future damage to the induction coil, regular maintenance is essential. This includes inspecting the coil for any signs of wear, cleaning it regularly, and ensuring proper insulation. Additionally, regular maintenance can help identify any potential issues early on and prevent costly repairs.

Conclusion:

The repair method of the induction coil of a medium frequency electric furnace plays a vital role in maintaining its performance and prolonging its lifespan. Whether it involves coil replacement or repair, proper inspection, and maintenance are essential. By following these repair methods, the induction coil can be restored to its optimal condition, ensuring efficient and safe operation of the medium frequency electric furnace.