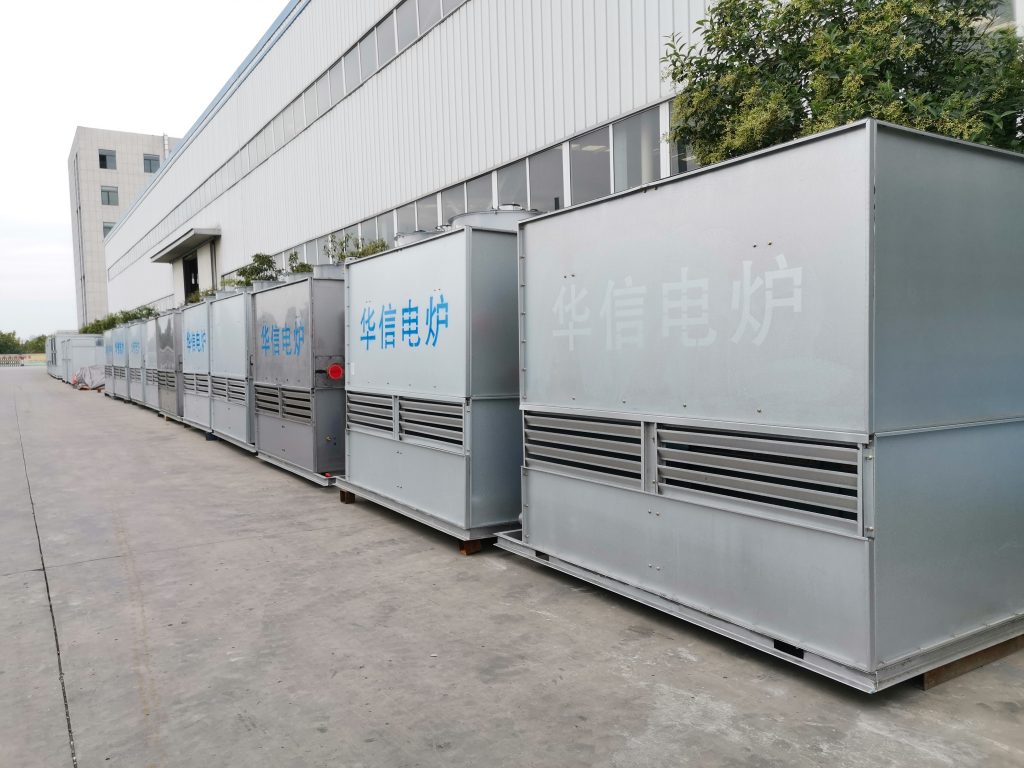

Medium frequency furnace closed water-cooling tower

Frequency electric furnace is a thyristor variable frequency induction heating device, which generally uses medium frequency heating. During its operation, the thyristor, capacitor, reactor and heating coil all need to be cooled down. The cooling temperature generally requires the cooling water entering the intermediate frequency electric furnace to be less than 40°C. Therefore, the closed cooling tower emerged in the intermediate frequency electric furnace cooling system and became the standard equipment for circulating cooling of the intermediate frequency electric furnace.

Medium frequency electric furnace closed cooling tower consists of

The intermediate frequency electric furnace closed cooling tower is an intermediate frequency electric furnace cooling system, which is mainly composed of copper cooling coil, upper shell, lower shell, cooling fan, drainer, spray system, cooling water tank, main circulation water pump, temperature control system, etc. composition.

1. Cooling tower main body: including tower body, radiator, ventilation, etc.

2. Circulating water system: including water pumps, pipes, valves, etc., used to circulate water to and discharge from the cooling tower.

3. Control system: including temperature sensors, controllers and necessary actuators, used to monitor and control the working status of the cooling tower.

4. Water replenishment system: used to replenish the water loss of circulating water.

5. Sewage system: used to remove impurities and sediments in circulating water.

6. Power system: Provides power for the motor and control equipment of the cooling tower.

The function and principle of closed cooling tower for medium frequency electric furnace

1. The function of the closed cooling tower of the intermediate frequency electric furnace is to take away the heat generated by the intermediate frequency furnace during its operation to maintain the normal operation of the intermediate frequency furnace. The closed cooling tower transfers the heat generated in the furnace body to the cooling water through the circulating water system, thereby reducing the temperature of the intermediate frequency furnace and ensuring its normal operation. The characteristic of this cooling tower is that it can effectively control water circulation, avoid water waste, and improve cooling efficiency.

2. The principle of the intermediate frequency electric furnace closed cooling tower is to use water to circulate in the intermediate frequency electric furnace closed cooling tower and carry out heat exchange with the air in the cooling tower to take away the heat of the Haishan electric furnace. During operation, the cooling water is transported to the cooling system of the Haishan electric furnace through a circulation pump, and then after absorbing heat through the furnace body, the heated cooling water returns to the cooling tower. In the closed cooling tower of the intermediate frequency electric furnace, the cooling water comes into contact with the air through the packing layer, and the heat in the cooling water is transferred to the air by means of steam-water exchange, thereby reducing the temperature of the cooling water. Then, the closed cooling tower of the intermediate frequency electric furnace re-transmits the cooling water to the cooling system of the intermediate frequency furnace to complete the cycle.

Conditions for use of medium frequency electric furnace closed cooling tower

1. The altitude does not exceed 3000m<p

2. The environment is within the range of 3-40C; (antifreeze measures are required in areas below 0℃). It is recommended to use our company’s antifreeze patented closed cooling tower.

3. The average relative humidity in the area of use cannot exceed

4. There is no conductive dust, explosive gas and corrosive gas that can seriously damage metal and insulation around the environment.

Application scope of medium frequency electric furnace closed cooling tower

1. Complete sets of induction heating equipment, diathermy equipment, and smelting equipment

2. Complete sets of high-frequency, medium-frequency power supplies and induction heating and quenching equipment

3. Die casting machine, injection molding machine

4. Rectification equipment, solder mask machine

5. Single crystal furnace, continuous casting crystallizer, glass melting furnace

6. Food, chemical industry, air compressor, central air conditioner

Advantages of medium frequency electric furnace closed cooling tower

Compared with traditional open cooling towers, medium frequency electric furnace closed cooling towers have higher cooling efficiency, lower energy consumption and better environmental performance. Since the closed cooling tower adopts a fully closed circulation system, the water quality is effectively guaranteed, reducing corrosion, scaling, clogging and other problems, and extending the service life of the intermediate frequency furnace. In addition, the closed cooling tower also has the characteristics of high degree of automation, easy operation, saving time and effort. It can automatically start and stop the fan and spray system according to the temperature of the circulating water, without manual intervention, saving time and effort. The specific advantages are as follows:

1. The closed cooling tower of the medium frequency electric furnace adopts a closed cycle to prevent pollution of the cooling water, effectively protect the internal equipment and extend the service life;

2. The closed cooling tower of the medium frequency electric furnace has a professional and efficient water collector, which controls the operating drift rate to less than 0.001%;

3. The closed cooling tower of the medium frequency electric furnace adopts an anti-freeze and energy-saving design, and is cold-resistant and frost-resistant;

4. The closed cooling tower of the medium frequency electric furnace does not require a water collection tank and saves land;