Matters needing attention of medium frequency induction furnace

The medium frequency induction furnace has been paid more and more attention because of its fast heating speed, uniform heating temperature, energy saving and environmental protection. At present, it has been widely used in forging, casting and metal quenching and tempering heating. Medium frequency induction furnace is also a non-standard heating equipment, which has some special rules and maintenance methods in use.

- The inductor of medium frequency induction furnace, also known as furnace head, is a spiral coil made of rectangular copper tube. It is professionally designed according to the length, diameter, heating temperature and heating beat of heating workpiece, which can ensure the heating temperature of workpiece and temperature difference between core and surface.

- In order to protect the induction coil, the inductor of medium frequency induction furnace needs to be equipped with furnace lining. At present, there are basically two kinds of furnace lining assembly, one is binding furnace lining, the other is assembled furnace lining.

- When the inductor of medium frequency induction furnace is in use, the oxide scale falling off from the heated workpiece should be cleaned in time. If the furnace lining is damaged, or there are cracks, cracks, if not cleaned in time, one is easy to ignite, causing medium frequency power over-current protection, the other is easy to break down the inductor coil and cause inductor turn to turn short circuit. In principle, the oxide scale in the inductor furnace shall be cleaned at least once every shift (8 hours).

- It is necessary to observe and maintain the lining of medium frequency induction furnace frequently. If the lining is knotted, knotting material must be used to fill the cracks when they are less than 2mm. If the cracks are more than 2mm, the lining must be knotted again; If it is a fabricated furnace lining, it must be replaced. In order to avoid the oxide scale falling into the gap and causing turn to turn short circuit and burning the inductor.

- The inductor coil of medium frequency induction furnace is cooled by water. There must be enough water flow and water pressure to ensure the normal cooling of copper tube of inductor. Therefore, the working pressure of cooling water should not be less than 0.2 ~ 0.3MPa, the inlet temperature should be less than 35 ℃, and the outlet temperature should be less than 55 ℃. If the water pressure is not enough, it will cause the sensor coil gasification and heating. If it is not found in time, the copper pipe will break and the water will overflow. And the inductor is working at high temperature, at this time, it is likely to explode, so the water cooling of inductor in medium frequency induction furnace is very important.

- The new inductor just put into production in medium frequency induction furnace must be baked with low power (generally about 30kW), and the workpiece should be heated in the induction furnace for about 2 hours. The residual water in the lining is removed to ensure the service life of the lining.

- Once the dry guide rail (without water) of medium frequency induction furnace is worn and deformed, it must be replaced. It is forbidden to use the furnace lining as the guide rail for heating workpiece.

- The water-cooled guide rail of medium frequency induction furnace is worn during use. Generally, the wall thickness of water-cooled guide rail is 2mm. Therefore, the use of water-cooled guide rail has a certain period of time. If there is too much wear, it must be replaced. Otherwise, once the water leaks, it will cause the rapid cooling of the furnace lining and directly affect the effect of the furnace lining.

- The water-cooled guide rail in the inductor of medium frequency induction furnace is actually the moving track of heating workpiece, which has been working at high temperature. If the water supply is not enough or the water pressure is not enough, it will produce gasification, burning, deformation, heating workpiece can not pass through the sensor. Therefore, the water cooling of water-cooled guide rail is also very important.

To sum up, medium frequency induction furnace in the process of use must also be observed while checking. If problems are found, they should be dealt with in time. Only in this way can the normal use of the medium frequency induction furnace be ensured without affecting the production.

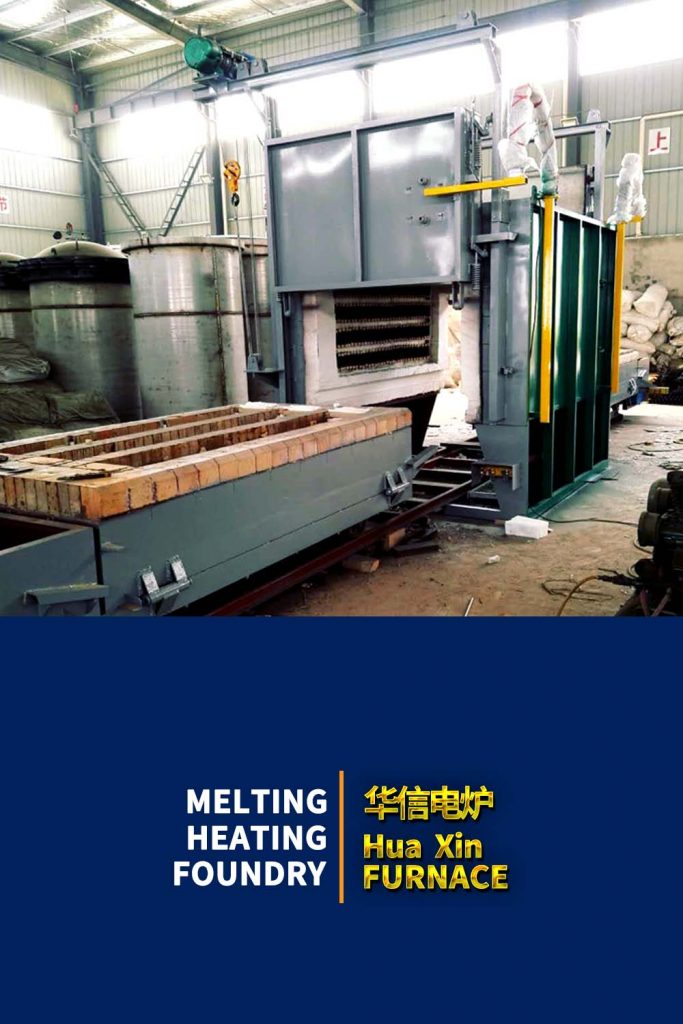

Shandong Huaxin Electric Furnace Co., Ltd. is a professional induction furnace manufacturers, specializing in the production of: medium frequency heating furnace, medium frequency melting furnace, medium frequency electric furnace, one driven two series resonant medium frequency induction furnace, induction diathermy furnace, induction heating equipment, medium frequency induction furnace, induction furnace, medium frequency induction heating furnace, induction heating power supply, diathermy furnace, forging heating furnace, quenching and tempering equipment Medium frequency induction heating, medium frequency heat treatment quenching and tempering production line and other heat treatment equipment series, we with advanced technology, high quality products, excellent service, dedicated to serve the majority of users at home and abroad.