Knowledge of building medium frequency furnace

Medium frequency furnace building is also called furnace lining knotting, in order to protect the induction coil from damage. For example, the coil knotting of the medium frequency heating furnace and the furnace building of the medium frequency melting furnace are different in material, furnace building method and use method.

The induction coil diameter of medium frequency heating furnace is generally designed according to the blank diameter and lining thickness, so there are two ways to build the furnace: one is the bonded lining, the other is the fabricated lining. The refractory temperature of bonded furnace lining is 1300 ℃, and that of fabricated silicon carbide furnace lining is 1350 ℃. The lining thickness of medium frequency heating furnace is generally 30-40mm, and the way of building furnace is vibration and knot after adding water; The assembled type is relatively simple, and the formed furnace lining is wrapped with asbestos for protection, so as to avoid the damage of SiC furnace lining caused by thermal expansion and cold contraction.

The lining of medium frequency smelting furnace is required to have a fire resistance of 1750 degree, which is much higher than that of heating furnace; The furnace building method is divided into wet beating and dry beating. At present, the more popular furnace building method is dry beating. Different kinds of lining materials are used according to different smelting varieties. The lining materials of smelting furnace are divided into acid lining materials, alkaline lining materials and neutral lining materials. The knotted lining should be filled and compacted layer by layer, and the thickness of each layer should not exceed 50 mm. In the process of knotting, special attention should be paid not to damage the stone cloth, otherwise the damaged part of the stone cloth will cause sand leakage, If any damage is found on the asbestos cloth, it should be repaired immediately. After the completion of furnace construction, the furnace should be dried to ensure that the furnace lining is strong and durable and reaches the designed service life.

The construction of medium frequency furnace is a work with certain technical content. According to the different use purposes of medium frequency furnace, different construction methods should be adopted to ensure the normal use of medium frequency furnace and improve the service life of medium frequency furnace.

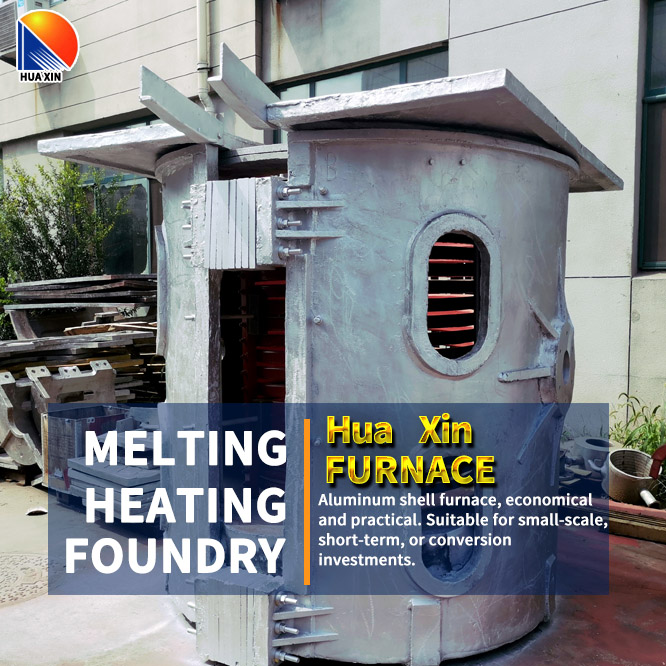

Shandong Huaxin Electric Furnace Co., Ltd. is an excellent induction furnace manufacturers in China, specializing in the production of: medium frequency heating furnace, medium frequency melting furnace, medium frequency electric furnace, one driven two series resonant medium frequency induction furnace, induction diathermy furnace, induction heating equipment, medium frequency induction furnace, induction furnace, medium frequency induction heating furnace, induction heating power supply, diathermy furnace, forging heating furnace, quenching and tempering equipment Medium frequency induction heating, medium frequency heat treatment quenching and tempering production line and other heat treatment equipment series. With advanced technology, high-quality products and excellent service, we are dedicated to serving our customers at home and abroad.