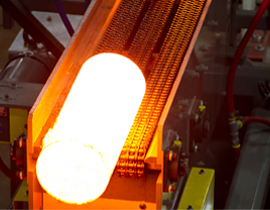

Energy saving and environmental protection medium frequency furnace

1. Analysis of energy saving of intermediate frequency furnace:

The intermediate frequency furnace uses electric energy and uses the principle of electromagnetic induction heating to convert electric energy into heat energy to heat the metal. Unlike coal, gas, and heavy oil heating methods, it does not need to heat the inner cavity of the furnace, and heats the workpiece by conducting heat through the inner cavity; The electric current is generated on the workpiece by electromagnetic magnetic force lines to heat the workpiece. Therefore, the intermediate frequency furnace has high heating efficiency, low heat consumption and energy saving.

Due to the self-heating and fast heating speed of the intermediate frequency furnace, the contact time of the workpiece with air is short during the heating process, the surface oxidation is small, and the workpiece burns less, thereby improving the material utilization rate and saving materials, which is a guarantee for the energy saving of the intermediate frequency furnace.

2. Environmental analysis of intermediate frequency furnace:

The heating of the intermediate frequency furnace adopts electromagnetic induction heating. Unlike coal burning heating and heavy oil burning heating, the smoke and dust generated by the heating of the intermediate frequency furnace are only caused by the heating of the oil, impurities, rust, and dust on the workpiece itself. Take it easy.

3. Heating quality of intermediate frequency furnace:

The heating temperature of the intermediate frequency furnace is uniform and the heating temperature is stable due to the self-heating of the workpiece, and the heating quality of the workpiece is greatly improved. The tempo control of the intermediate frequency furnace, the stability of current and voltage, and the application of the temperature sorting device greatly improve the heating quality of the intermediate frequency furnace.